Complēt™ PKE Formulations

Improve Chemical Resistance, Reduce Carbon Footprint

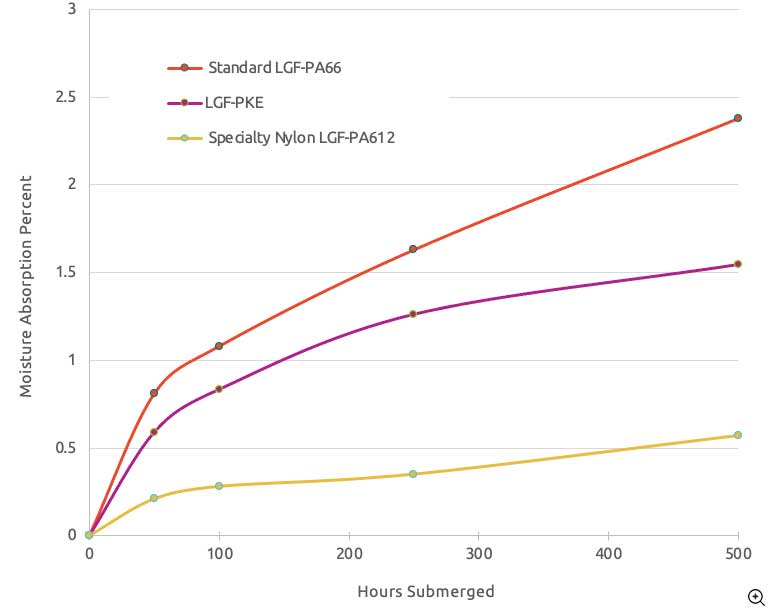

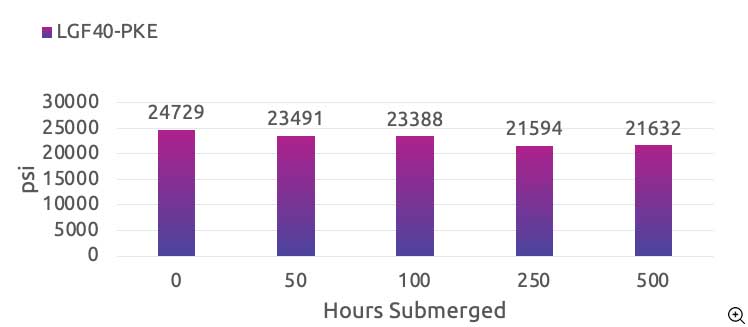

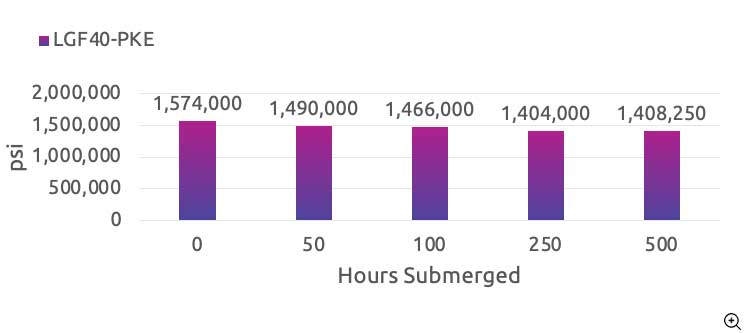

Complēt™ PKE polyketone formulations are long glass fiber reinforced polyketone solutions for structural applications using metal today. These materials are semi-crystalline and deliver excellent chemical resistance, low moisture uptake, and dimensional stability similar to nylon (PA6 and PA66). Polyketone has lower coefficient of friction, similar to acetal, giving it improved wear resistance.

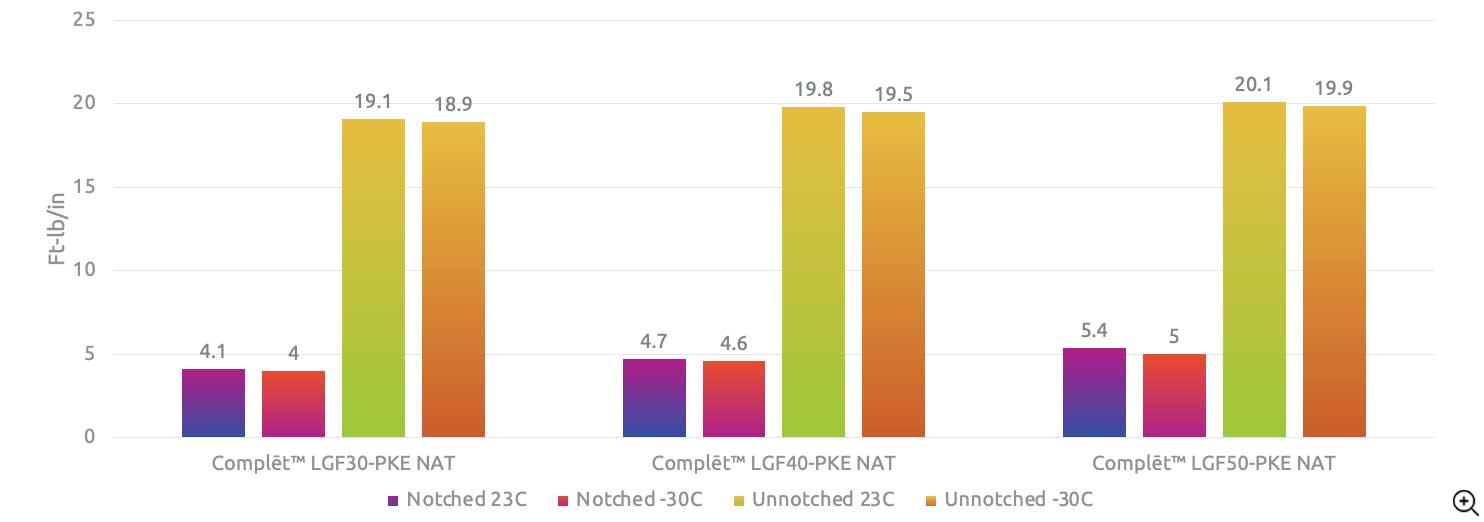

These formulations also offer over 2x higher impact properties than short fiber reinforced, polyketone solutions and, further, maintain impact properties in cold and demanding environments making them ideal candidates for outdoor applications.

Complēt PKE formulations offer a reduced carbon footprint as a result of the base resin, helping to improve sustainability over the end product lifecycle. Manufacturing polyketone results in 61% less carbon dioxide (CO2) than producing PA66 and 46% less than PA6.

These materials are for use in applications in moisture-rich environments or for applications in which chemical resistance or cold impact performance is critical. Market examples include Industrial (pipes, tubing, fluid management), Electrical & Electronics (connectors, battery components), Transportation (under-the-hood fuel/ chemical contact components), and Oil & Gas (fuel pump components, fuel doors).

优势

- 耐化学腐蚀性

- Maintain high impact performance at low temperatures

- 低吸湿性

- Dimensional stability comparable to nylon

- Eco-conscious alternative to nylons

- More cost-effective solution than specialty nylon solutions

- Available in non-PFAS* formulations to achieve a UL 94 V-0 flame rating at 1.5 mm

| Technical Property¹ | 测试方法 | Complēt LGF30-PKE NAT | Complēt LGF40-PKE NAT | Complēt LGF50-PKE NAT |

|---|---|---|---|---|

| 比重 | ASTM D792 | 1.47 | 1.54 | 1.66 |

| Tensile Strength (Yield)(psi) | ASTM D638 | 21,100 | 24,700 | 26,400 |

| Tensile Modulus² (psi) | ASTM D638 | 1,150,000 | 1,570,000 | 2,150,000 |

| Flexural Modulus³ | ASTM D790 | 1,120,000 | 1,480,000 | 2,030,000 |

| Flammability (1.5 mm) (non-PFAS* options available) | UL 94 | V-0 | V-0 | -- |

| ¹Data based on single lot of lab generated samples. Values are not constructed as specifications. ²0.20 in/min ³0.05 in/min | ||||

| *Non-PFAS flame-retardant (FR) grades are manufactured without intentionally added PFAS-based raw materials. They are not available for purchase and are not intended for use in countries outside of North America and South America. | ||||

| 名称 | 类别 | 描述 | |

|---|---|---|---|

| Automotive Aftermarket Overview | Application Overview | Overview of the needs within automotive aftermarket and the long fiber thermoplastic (LFT) technologies to meet those needs | 查看 |

| Avient Long Fiber Technology | 视频 | Provides structural performance that can go head-to-head with metals at a fraction of the weight | 查看 |

| Benefits of LFT | 白皮书 | Explore the unique capabilities of specialty long fiber reinforced composites | 查看 |

| Complēt™&OnForce™ 长纤维增强热塑性复合材料 - 加工指南 | Processing & Design Guides | Complet&OnForce LFT 制备和成型工艺关键要素指导 | 查看 |

| Complēt™ 和 OnForce™ 长纤维增强热塑性复合材料 - 设计指南 | Processing & Design Guides | 下载本指南,了解如何设计出经久耐用的肋条、凸台和其他特征,加工 LFT 材料的更好方法,如何最大限度地减少零件缺陷,以及更多关于 Complēt™ 和 OnForce™ 长纤维增强热塑性复合材料的信息 | 查看 |

| Complēt™ LFT - 更坚固。更具韧性。更轻。 | 视频 | 比较长纤维热塑性塑料与其他材料的强度、韧性和重量 | 查看 |

| Complēt™ PKE Formulations | Product/Service Overview | Complēt PKE 配方的主要特性、市场和应用概述 | 查看 |

| Complēt™/OnForce™ LFT Overview | Product/Service Overview | 借助轻质长纤维增强热塑性塑料优化刚度、强度和韧性,以获得结构性能。 | 查看 |

| Long Fiber Reinforced Thermoplastic (LFT) Solutions for Bicycles | Application Graphic | Explore long fiber reinforced thermoplastic (LFT) solutions that meet various bicycle application demands | 查看 |

| Long Fiber Technologies Application Development | Product/Service Overview | Avient long fiber technologies application development center bulletin highlighting services including design support, material validation, simulation support, and in-house prototyping | 查看 |

| Long Fiber Thermoplastics for Brackets and Latches | Application Overview | Key benefits and data for long fiber thermoplastic (LFT) to replace metal for brackets and latches | 查看 |

| Nylon Alternatives for Powersports Applications | Application Overview | Overview, key characteristics and technical data on nylon alternatives for powersports applications | 查看 |

| Replacing Aluminum with Long Fiber Thermoplastics (LFT) | Application Overview | Key factors and comparisons to consider when replacing aluminum with long-fiber-reinforced thermoplastic (LFT); including processing and material performance summaries | 查看 |